OVERVIEW

Who we are

PT Adhi Petrotama Energi (PT APE) is the leading logistics automation solution in Indonesia. We have redesigned, reworked and are currently operating 9 terminals out of Pertamina’s 110 in Indonesia, representing 40% of the national fuel consumption. We are among the very few companies in the world who have successfully applied automation and integrated the entire downstream supply chain. From receiving fuel to the terminal, to dispensing at the gas station, everything can be automated, unmanned, and be monitored in a single app.

Established in 2007 and headquartered in Indonesia’s two largest cities Jakarta and Surabaya, it is fitting then, that PT APE started by fully automating and operating Indonesia’s two largest fuel distribution facility belonging to the Indonesia state oil company, PT Pertamina’s Plumpang Fuel Terminal in Jakarta as well as Perak Fuel terminal in Surabaya. This resulted in a drastic boost in efficiency and working losses reduction, which led to further work in 8 other Pertamina sites as well as contract works with Puma Energy and Shell throughout Indonesia for the next 12 years.

At present, our logistics automation solution is more advanced and diverse than ever. The modular nature and scalability of our suite allows speedy implementation and customizability to your company’s unique needs.

We would be honored to have your trust in delivering the stellar results to you as our customer.

SOLUTIONS

TERMINAL AUTOMATION SYSTEM

Unmanned Filling Operation

- Fast fill-rate with precise volume control (error < 0.05%).

- Load rack control and automation

- Strict driver access verification

- Regularly calibrated meters with multiple daily spot check

- ESD and grounding safety system integration

Tank Storage Monitoring

- Tank gauging integration.

- Industry standard volume calculations

- Alarm and event management

- Automatic uploading of transaction and inventory data to SAP.

- Daily automatically generated physical inventory reports

- Book vs physical reconciliation (gain/loss)

Tank Storage Automation

- Automatic tank storage receiving and distributing operations with actuated valves.

- Automated radar tank gauging system

- Integrated safety interlocks

Fleet Management

- Unmanned health monitoring check-in station.

- Automated driver booking and scheduling

- Facility access

Order and Delivery

- App based purchase order system.

- Automated routing for multiple destinations based on machine learning

- GPS tracking of fleet

Inventory Accounting

- Order and tracking management.

- All tank transactions automatically uploaded to SAP.

- Automatically generated daily report

Data Security

- Secure cloud database.

- Encrypted and firewalled network system

- ISO 27001 (information security management system) compliant

The system does everything so you don’t have to

PT Adhi Petrotama Energi’s Terminal Automation System is a comprehensive terminal-wide system that seamlessly integrates both the operation side and the business process side of running a terminal. We utilize various hardware and software to provide a seamless integrated platform to run your terminal.

The entire system is fully automated and unmanned. The data can be monitored through a concise dashboard, available on mobile app and web browsers.

Whether you are a single, independently-operated liquid terminal, regional storage, pipeline or distribution company, we can automate and manage by fully integrating your operation and business process.

Executive summary at your finger tips, anytime, anywhere

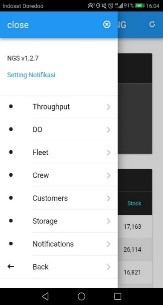

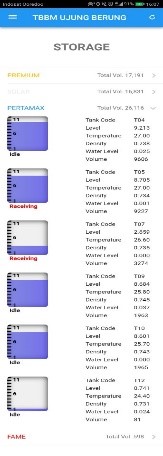

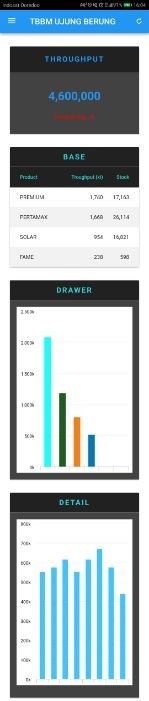

The NGS Mobile app is a dashboard that display both key and detailed metrics of the entire supply chain. The app runs on both iOS/Android mobile platform and is customizable to fulfill your business needs.

It features a cascading menu structure that displays more detail as we go down the hierarchy. The executive can gleam the state of operations at a glance through the sleek and concise layout, and obtain further detail if needed. The application covers the entire downstream supply chain, spanning the receipt of liquid material at the terminal to the inventory and POS for individual distribution outlets.

Good for the environment. Good for your bottom line.

Any losses is too much loss. That is why we built Indonesia’s first ever Vapor Recovery Unit. We worked with VOCZero to design, fabricate, install and operate the VRU unit at PT Pertamina’s Plumpang fuel terminal in Jakarta. The main objective was to reduce environmental impact by controlling emission of volatile organic compounds (VOC) to the atmosphere, but in order to make the project economically feasible we needed to ensure profitability for the client. On February 2018 the VRU unit went life delivering consistently above 0.1% recovery rate, rapidly recouping the unit’s investment cost.

The installation connects the vapor space of storage tanks, filling shed, and the tank trucks to the VRU, creating a closed vapor loop that reduces the terminal’s VOC emission to below 35 g/m3.

The reduction of the terminal’s carbon footprint, raised safety profile and excellent recovery rate marked this project as a monumental success. We look forward to working with you towards such an excellent outcome.

Sit back, relax, and let us take care of it.

Our goal is to help keep you operating at peak efficiency 24 hours a day, 365 days a year. To that end, we have the Operation Support Center (OSC).

Our OSC personnel are not only trained to set up and implement system solutions, but also offer technical support to ensure that your system is running smoothly and well maintained at all times. We are capable of providing on-site support in short notice to assist with any technical issues that may arise as well as run tests to ensure that your system is always at its top performance.

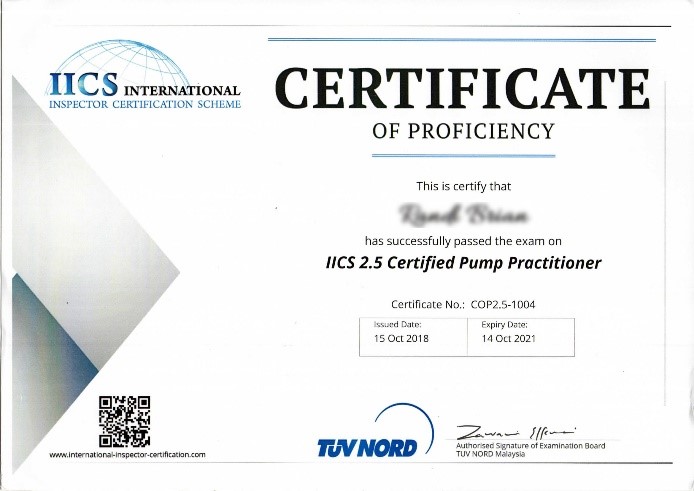

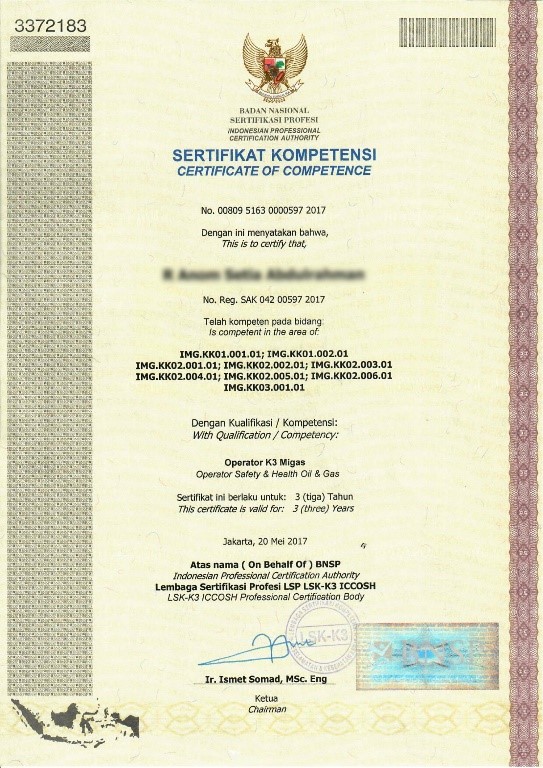

All our technical support personnel are qualified and certified by our various principals, as well as trained in proper safety procedures.

Contact

Contact Us

Address

Menara Kuningan, 10th floor. Jl. H. R. Rasuna Said No.5, RT.6/RW.7, Kuningan, Karet Kuningan, Kecamatan Setiabudi, Kota Jakarta Selatan, Daerah Khusus Ibukota Jakarta 12940

Call Us

(021) 30014999

Email Us

admin@adhipetro.com